Meaningful Art for the 21st Century

The Lost Wax Process

A Seven-Thousand-Year Tradition in Casting Bronze: The Lost Wax Process

As the early cave men discovered, when copper is thrown into a fire, it melts and can be made into shapes. Then some time between 3000-4000 B.C. a small miracle happened: tin was mixed with the copper and the resultant hybrid was stronger than either metal alone. The Bronze Age commenced with this discovery.

Modern methods employ the techniques that have been used for millennia in creating metal sculptures, although new materials have been introduced to perfect the lost wax process.

The Lost Wax Process: An Overview of the Technique

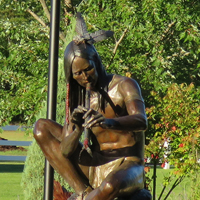

The making of The Tracker by Ed Natiya, commissioned by Bickers/Hosche Collection 2013

-

Create Clay Original

-

Coat clay with rubber to form mold; open mold and remove clay original

-

Pour wax into rubber mold; remove hardened wax and correct/refine details

-

Dip wax into silica slurry or ceramic to form mold ("invest the wax")

-

Kiln-fire to harden investment (mold) and melt out wax (the "lost wax" process)

-

Pour molten bronze into the investment where wax was "lost"

-

Chip off investment, remove sprue system and clean up surface ("chase" the bronze casting)

-

Heat bronze and treat with chemicals to obtain desired color and finish (patina)

-

Mount on base